News

MBBR Classifications & Features

1. Classifications

Linpor MBBR

The Linpor MBBR process mainly uses polyurethane sponge as the carrier and is mainly used for the transformation of municipal sewage systems;

Kaldnes MBBR

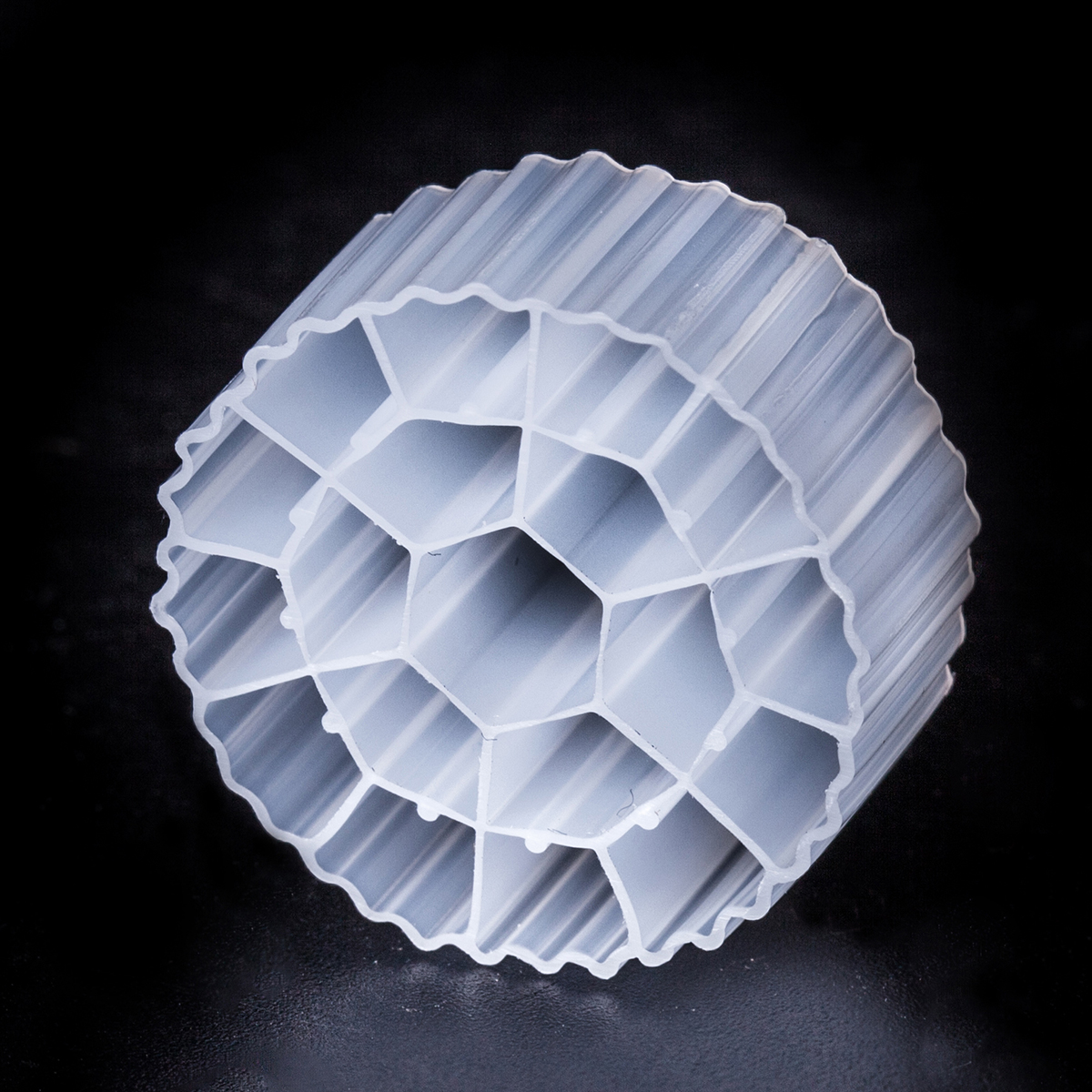

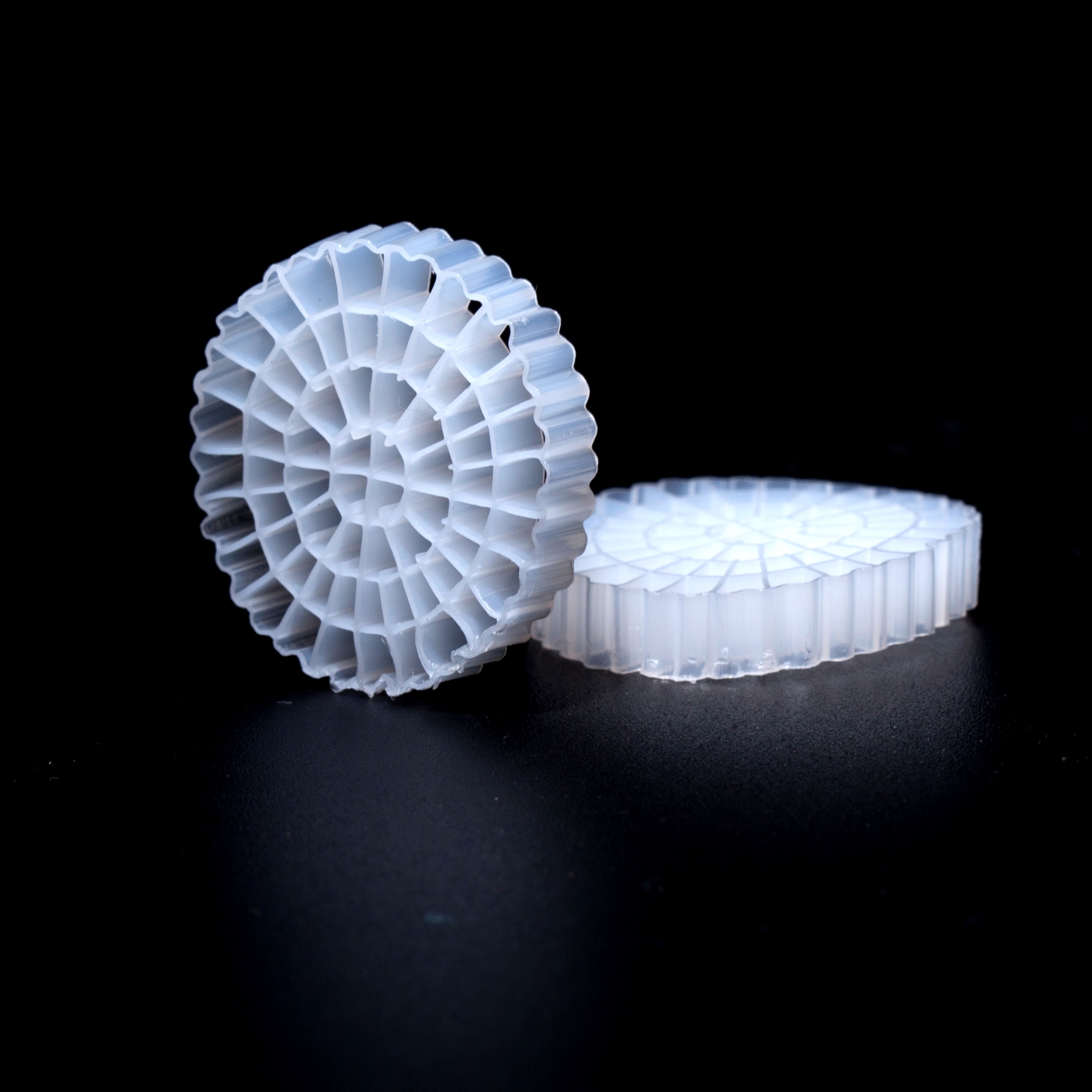

Kaldnes MBBR process, the biological carrier is mostly made of polyethylene material, with a Pall ring structure;

Levapor MBBR

Levapor MBBR process, Levapor technology was developed by Bayer, Germany. Through the surface treatment of Linpor carrier, 30% activated carbon powder is absorbed, so that the specific surface area of Levapor is as high as 20000m2/m3, which is 10-20 times that of the former two. Levapor MBBR is suitable for high concentration and difficult Degradation of organic matter and high ammonia nitrogen and nitrate are mainly used in the treatment of high-concentration, difficult-to-degrade, high-ammonia organic wastewater in the chemical, pharmaceutical, and pesticide industries.

2. Features

Rapid carrier filming mechanism; special modified formula and processing technology are used to accelerate filler filming. Specific trace elements and special surface treatment processes are added to the carrier to promote rapid growth of microorganisms in the water. Propagation and formation of organisms, different water quality and conditions have differences in the progress of filming, generally only 3-15 days, the fastest only takes 1 day.、

With a huge specific surface area, it provides support for the attachment and growth of a large number of microorganisms; it is conducive to the growth of various microorganisms, not only providing space for the growth of heterotrophic bacteria, but also creating conditions for the growth of autotrophic bacteria, and biological denitrification and phosphorus removal Lay a solid foundation.

Super decarburization, ammonia and nitrogen removal ability; the carrier provides a comfortable and safe environment for the mass reproduction of microorganisms, and the species of organisms are constantly enriched. As it is not restricted by the mud age, nitrifying bacteria also multiply on a large scale. The huge biological population makes the water Organic matter and ammonia nitrogen quickly decompose.

Excellent load shock resistance; the change of influent COD concentration is large, but the change of COD removal rate is small, indicating that MBBR has the advantage of stable effluent quality within a certain concentration range.

Flexible and diverse engineering application methods; it can be used in different stages of aerobic, anaerobic and anoxic processes, and satisfactory treatment effects can be easily obtained by adding fillers.

Simple operation and maintenance conditions, no support, easy fluidization, energy saving; no support, and can save sludge backflow, avoid sludge expansion, floating and loss problems, easy operation and maintenance. Proper specific gravity (0.95~0.98g/cm3 before filming), make the filler float while staying, and stay in a suspended fluidized state under aeration, which minimizes energy consumption; the easy fluidization of the filler increases the resistance to bubbles The impact and cutting of the oxygen increase the utilization rate of oxygen and reduce the energy consumption of aeration. Under the same conditions, the aeration volume can be reduced by more than 10%.

CATEGORIES

LATEST NEWS

- MBBR Classifications & Features2020-08-20

- Background and Advantages of MBBR process2020-08-14

- MBBR System process N Removal2020-06-07

- A few MBBR Porcess for water treatment2020-05-14

- How to Install Tube Settler?2020-04-27

CONTACT US

Contact: Nana

Phone: 86-15267462807

Tel: 86-15267462807

Email: sales@nihaombbr.com

Add: Linping,hangzhou, Zhejiang, China